Lubricants play a critical role in keeping engines and machinery running smoothly, but their performance is never constant. Lubricants — especially automotive lubricants — play a critical role in keeping engines and machinery running smoothly, but their performance is never constant.Factors like temperature and climate can dramatically change how a lubricant behaves, often determining whether a system runs efficiently or fails prematurely. Understanding the climate impact on lubricant performance helps users select the right oil for reliable, year-round protection.

High heat can make oil thinner, reducing its protective layer. Extreme cold, on the other hand, thickens lubricants, slowing their flow and causing extra friction during start-up. Likewise, humidity, dust, and altitude can alter how lubricants protect moving parts. These environmental variables define how efficiently lubricants function in real-world applications.

Understanding the climate impact on lubricant performance is essential for drivers, engineers, and equipment operators who need consistent performance under changing environmental conditions. This guide from SiNDA Oil explains how temperature and environmental factors influence lubricants — and what you can do to maintain stability across climates.

Understanding the Basics: How Lubricants Work

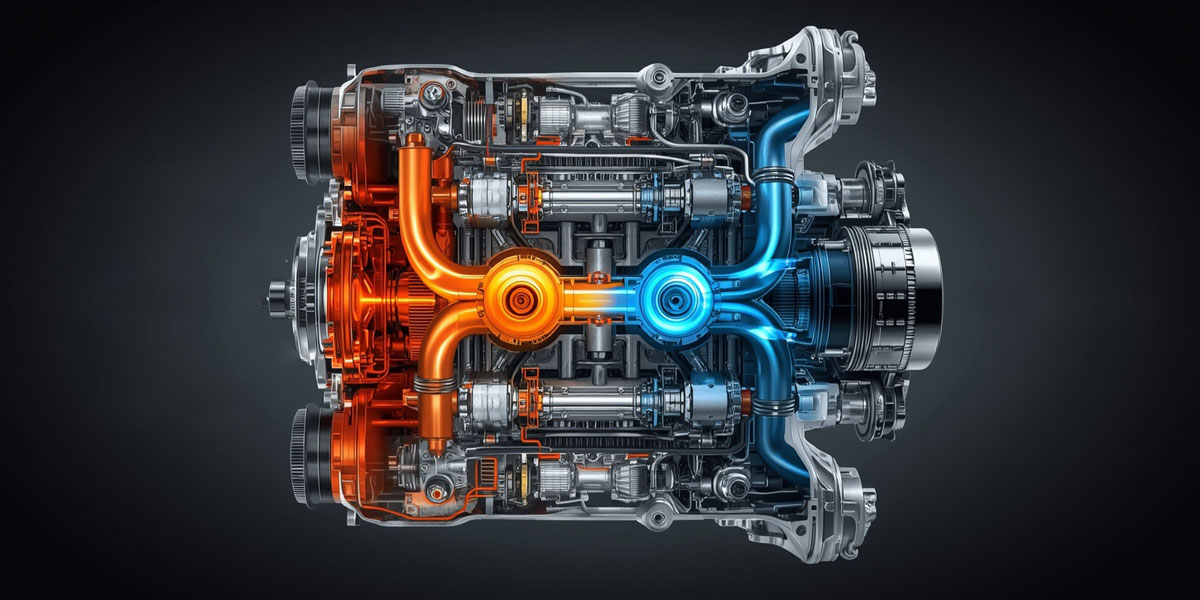

Lubricants are the unsung heroes inside every engine and machine. Their primary purpose is to reduce friction and heat between moving parts. By creating a thin film between metal surfaces, lubricants prevent direct contact, minimizing wear, noise, and energy loss.

Beyond that, good-quality lubricants cool and clean the system while forming a barrier against oxidation and corrosion. When this balance is maintained, engines perform smoothly and last much longer — but that balance can easily be disrupted by climate impact on lubricant performance.

The Role of Lubricants in Reducing Friction and Heat

Every moving surface in a vehicle — from pistons to bearings — generates friction. Without proper lubrication, these parts would grind against each other, producing excess heat and rapid wear. The right lubricant forms a protective layer that allows these surfaces to glide effortlessly.

This protective layer is directly influenced by temperature. If the oil becomes too thin in hot conditions, it can no longer separate the metal parts effectively. In contrast, when oil thickens in cold weather, it struggles to circulate quickly enough, leaving areas unprotected during start-up. These changes show how climate impact on lubricant performance directly affects engine efficiency and reliability.

Why Temperature and Environment Matter More Than You Think

Many assume that any oil can work under all conditions, but that’s not true. Temperature and environment determine how efficiently a lubricant performs. A lubricant that works perfectly in the mild climate of Europe might fail in the heat of the Middle East or the freezing cold of Northern regions.

That’s why understanding climate impact on lubricant performance is vital. Factors like air temperature, humidity, and altitude affect how oils behave — and choosing the right formulation ensures smoother operation, lower maintenance costs, and longer equipment life.

How Temperature Affects Lubricant Performance

Temperature is the single most influential factor affecting lubricant behavior. As the environment changes from hot to cold, so does the oil’s viscosity — its resistance to flow. In simple terms, viscosity determines whether your oil feels “thick” or “thin.”

A lubricant that performs well at normal temperatures may behave very differently under extreme conditions. High heat reduces its protective qualities, while freezing cold makes it sluggish and slow to circulate. Managing climate impact on lubricant performance starts with understanding this temperature-viscosity relationship.

The Science of Viscosity and Flow

The Science of Viscosity and Flow

Viscosity defines how easily a lubricant moves between engine parts.

- At high temperatures, viscosity drops — the oil becomes thinner and flows easily, but may lose its protective strength.

- At low temperatures, viscosity increases — the oil thickens, making it harder to pump and circulate, especially during start-up.

That’s why modern lubricants are engineered to maintain stable viscosity across wide temperature ranges. The climate impact on lubricant performance is largely controlled through a high Viscosity Index (VI), which shows how much the oil’s viscosity changes with temperature. A higher VI means the oil stays stable and reliable across climates.

What Happens to Lubricants in Hot Conditions

When exposed to intense heat — such as in heavy traffic, industrial machines, or desert climates — lubricants face several issues:

- Thinning of the oil film, reducing protection.

- Faster oxidation and sludge formation.

- Increased wear and overheating risks.

High-quality synthetic oils are designed to resist these effects. SiNDA Oil’s formulations are tested to withstand severe heat, ensuring that climate impact on lubricant performance is minimized even in extreme desert environments.

Challenges of Cold Weather: When Oil Becomes Too Thick

In freezing temperatures, lubricants can become so thick that they struggle to reach critical engine parts. This causes:

- Hard starts and sluggish circulation.

- Higher friction during warm-up.

- Increased wear during cold starts.

Using oils with a low pour point or multi-grade viscosity (like 5W-30) ensures better fluidity in cold weather. These oils are specifically engineered to offset climate impact on lubricant performance in sub-zero environments.

Viscosity Index and Its Importance

The Viscosity Index (VI) is a critical factor in lubricant design.

- Low VI oils thin rapidly in heat and thicken drastically in cold.

- High VI oils remain stable, ensuring reliable protection in variable climates.

SiNDA Oil’s lubricants, formulated with a high VI, maintain consistent viscosity and protect against the adverse climate impact on lubricant performance across temperature extremes.

Climate Factors That Influence Lubrication

Temperature isn’t the only environmental factor that affects lubricants. Conditions like humidity, dust, and altitude also play a major role. Understanding how these contribute to climate impact on lubricant performance helps prevent unexpected mechanical issues.

Humidity, Moisture, and Corrosion Risks

In humid or coastal environments, water molecules can enter oil through condensation or leaks, leading to:

- Metal corrosion.

- Oil contamination and emulsion formation.

- Accelerated oxidation and sludge buildup.

Moisture-resistant lubricants and regular oil analysis are essential to reducing these risks and maintaining stable performance under diverse climates.

Dust, Altitude, and Air Quality

Dusty or high-altitude environments introduce contaminants that act like abrasives, damaging components and thickening oil over time. Using quality filters and sealed systems helps control the climate impact on lubricant performance in harsh outdoor conditions.

Seasonal Variations and Equipment Adaptation

Engines and machinery often face both summer heat and winter cold. These seasonal swings strain lubricants, testing their adaptability.

- In summer, oxidation and thinning are common.

- In winter, thickening and slow flow dominate.

Following seasonal maintenance routines and using multi-grade oils can effectively reduce climate impact on lubricant performance year-round.

Choosing the Right Lubricant for Different Climates

Choosing a lubricant isn’t just about brand — it’s about matching the formulation to environmental conditions. Whether in desert heat, coastal humidity, or mountain cold, selecting the right oil helps maintain efficiency.

Selecting the Correct Viscosity Grade

- For cold climates: thinner oils (0W-20 or 5W-30).

- For hot climates: thicker grades (10W-40 or 20W-50).

Always check OEM specifications. The wrong viscosity can amplify the negative climate impact on lubricant performance, causing wear and reduced efficiency.

Synthetic vs. Mineral Oils

Synthetic oils outperform mineral oils in extreme temperatures. They stay fluid in cold and resist oxidation in heat. SiNDA’s synthetic formulations are specifically designed to minimize climate impact on lubricant performance across global conditions.

Additives that Improve Temperature Resistance

Modern oils use advanced additives — antioxidants, anti-wear agents, detergents, and anti-foam compounds — to stabilize viscosity and extend oil life. These additives directly combat the climate impact on lubricant performance in demanding environments.

How SiNDA Oil Ensures Reliable Performance in Any Climate

At SiNDA Oil, performance is engineered — not left to chance. Partnering with Italian Petrol Company (IPC), SiNDA develops lubricants that meet or exceed European standards, tested in diverse climates worldwide.

By combining high-quality base oils with advanced additive chemistry, SiNDA ensures durability against oxidation, wear, and viscosity breakdown — minimizing the negative climate impact on lubricant performance across all temperature zones.

Key Takeaways and Practical Tips

Keeping lubricants in top condition year-round is simple with proper maintenance and awareness of climate impact on lubricant performance.

Tips:

- Check oil condition regularly.

- Follow seasonal oil-change intervals.

- Avoid mixing lubricant types.

- Use quality oil filters.

- Store oils in temperature-controlled areas.

Watching for warning signs — unusual noise, sluggish starts, or milky oil — ensures timely replacement and steady protection under any climate.

5 Proven Insights: Key Findings

Through extensive testing and analysis, five proven insights clearly show how the climate impact on lubricant performance determines reliability, efficiency, and protection across all environments:

- Temperature Controls Viscosity and Flow

Temperature is the most powerful factor influencing lubricant behavior. As heat rises, viscosity drops and protection weakens; as cold sets in, oils thicken and slow circulation. Controlling viscosity stability is the foundation for consistent performance in every climate. - Extreme Heat Accelerates Oxidation and Wear

Under high temperatures, lubricants oxidize faster, leading to sludge formation and metal-to-metal contact. Choosing thermally stable synthetic oils prevents these issues and maintains a strong protective film even in desert conditions. - Cold Weather Causes Sluggish Flow and Start-Up Stress

When temperatures fall below freezing, oils can become too thick to circulate efficiently, increasing engine wear during start-up. Multi-grade lubricants with low pour points help maintain smooth flow and protection in cold climates. - Humidity, Dust, and Altitude Affect Oil Stability

Moisture and airborne particles can contaminate lubricants, reducing their effectiveness and accelerating wear. Proper filtration, sealed systems, and moisture-resistant formulations are key to minimizing these environmental effects. - Synthetic Oils Offer Superior Climate Adaptability

Synthetic lubricants, with high Viscosity Index (VI) and advanced additive packages, resist both heat-induced breakdown and cold-induced thickening. They are the most effective solution to reduce the negative climate impact on lubricant performance under extreme operating conditions.

Conclusion

Conclusion

Temperature and climate directly shape how well lubricants protect, cool, and clean your machinery. From desert heat to freezing cold, the climate impact on lubricant performance determines system reliability and efficiency.

Through advanced technology and global testing, SiNDA Oil delivers lubricants engineered to perform consistently in every environment — ensuring smoother operation, longer lifespan, and dependable protection year after year.