The tensile strength of polymers is a cornerstone property in selecting and designing plastic components. In simple terms, it represents the maximum tensile stress a polymer can sustain before it fractures. Because plastics are viscoelastic, tensile response depends on temperature, strain rate, and prior processing—so understanding how tensile strength is defined, measured, and influenced is essential for safe, efficient products.

In this guide, you’ll learn what tensile strength is (and how it differs from yield and ultimate strength), how to interpret the stress–strain curve, which factors most strongly affect polymer strength, how standards like ASTM D638 and ISO 527 are applied, typical strength ranges across common families, and practical tactics to improve tensile strength in production.

What Is Tensile Strength at Break?

Tensile strength at break (often shortened to “tensile strength”) is the maximum true tensile stress at the instant of fracture during a uniaxial tension test. It is calculated by dividing the fracture load by the original cross‑sectional area of the gauge section.

- Not compression: Although strength can be measured in compression, tensile strength at break is strict from a tension test.

- Brittle vs. ductile: Brittle polymers (e.g., unmodified PS) may break with little elongation; ductile polymers (e.g., many polyamides) neck and draw substantially before fracture.

Related Terms and How They Differ

- Yield strength (σy): Stress at the onset of permanent deformation (yield). Some polymers do not show a clear yield point under certain conditions.

- Ultimate tensile strength (UTS): Peak stress on the engineering stress–strain curve. For some polymers, UTS and strength at break coincide; for ductile materials with extensive necking, break may occur after the UTS at a lower engineering stress.

- Tensile modulus (E): Initial slope of the stress–strain curve in the elastic region (a stiffness measure), not a strength.

Units and Conversions

Tensile strength is reported as force per area. Common units:

- SI: Pa, MPa (1 MPa = 1 N/mm²)

- US customary: psi (lbf/in²) and ksi (kpsi).

Quick conversion: 1 MPa ≈ 145 psi.

Stress vs. Strain (Refresher)

- Stress: σ = F / A₀

where F is tensile force and A₀ is original cross‑sectional area.

- Strain: ε = ΔL / L0

where L₀ is original gauge length; strain is dimensionless.

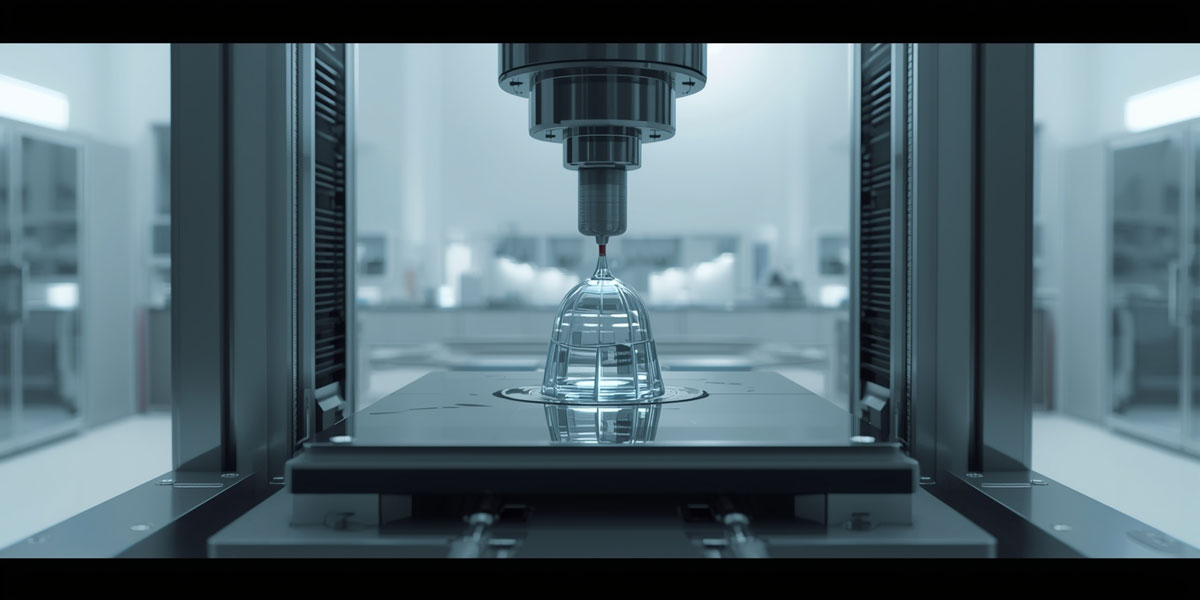

How Tensile Strength Is Measured

Polymer tensile properties are typically measured to ASTM D638 (plastics) or ISO 527 (plastics and composites). The two standards are broadly similar but not interchangeable; report the exact method, specimen type, and rate with any value.

Test Standards & Specimens

- ASTM D638: Dumbbell specimens, Types I–V. The choice depends on thickness and material behavior.

- ISO 527: Uses multipurpose dog‑bone specimens with specified gauge geometry.

- Orientation matters: Molded flow alignment and gate placement cause property anisotropy. Always note mold flow direction relative to the gauge.

Test Conditions and Data Comparability

- Strain rate: Faster rates generally increase measured strength for viscoelastic polymers. Typical settings: ISO 527 often uses 1 mm/min for modulus and 5 or 50 mm/min for strength/elongation; ASTM D638 rate is set by material class.

- Temperature & humidity: Elevated temperature lowers strength; absorbed moisture (e.g., in polyamides) can plasticize the matrix and reduce strength while increasing ductility.

- Conditioning: Preconditioning (e.g., 23 °C/50% RH, drying, or water conditioning) must be documented.

- Replicates & statistics: Use multiple specimens and report mean ± SD.

Reading the Stress–Strain Curve

- Elastic region: Linear portion; slope is E.

- Yield point: Start of plastic deformation (if present).

- Strain softening & necking: Localized thinning in ductile polymers.

- Strain hardening: Molecular orientation can raise true stress at large strains.

- Fracture: End of the test; tensile strength at break is calculated here.

Tip: For highly ductile grades, engineering stress can decrease after UTS due to necking even as the true stress rises. State clearly whether you report engineering or true values.

Factors Affecting the Tensile Strength of Polymers

Tensile strength is controlled by molecular structure, morphology, additives/reinforcements, processing‑induced orientation, and environmental variables. Key levers include:

1) Molecular Weight & Distribution

- Higher average molecular weight (Mw) increases chain entanglement density, generally raising strength up to a saturation region.

- Broad MWD can aid processability but may lower peak strength compared with a narrow, high‑Mw grade.

2) Crystallinity & Morphology

- Crystalline lamellae and tie‑molecules provide load paths; higher crystallinity (e.g., in HDPE, POM, PET, PEEK) often increases strength.

- Annealing can improve crystalline and relax residual stresses.

3) Molecular Orientation

- Flow‑induced orientation during injection molding, extrusion, film blowing, or fiber drawing can substantially increase strength along the orientation direction while decreasing it transverse to flow.

- Weld lines (knit lines) disrupt continuity and usually lower local strength.

4) Additives, Fillers, and Reinforcements

- Plasticizers lower glass transition temperature (Tg) and often reduce tensile strength while increasing flexibility.

- Mineral fillers (e.g., talc, CaCO₃) can stiffen but may not improve strength.

- Short glass fibers (GF) and carbon fibers (CF) can dramatically raise strength—fiber length retention and orientation are decisive.

- Coupling agents (e.g., silanes, maleated polyolefins) enhance matrix–fiber adhesion, improving load transfer.

5) Temperature, Moisture, Chemicals, UV

- Strength typically drops as temperature rises toward Tg (amorphous) or Tm (semi‑crystalline).

- Moisture plasticizes polar polymers (e.g., PA6/PA66), reducing dry‑as‑molded strength; conditioning protocols are critical.

- Chemical exposure (solvents, oils) and UV can embrittle or plasticize, affecting tensile performance.

6) Strain Rate and Notch/Defect Sensitivity

- Higher strain rates tend to increase measured tensile strength (less time for molecular relaxation).

- Notches, voids, knit lines, and surface defects act as stress concentrators; careful gate design and molding practice are essential.

Typical Tensile Strength Ranges (Representative Polymers)

Values below are indicative ranges for room temperature tests on standard specimens. Exact numbers vary with grade, conditioning, rate, and orientation. Report your method with any figure.

| Polymer / Compound | Tensile Strength at Break (MPa) | Notes |

| LDPE | 10–20 | Tough, low crystallinity |

| LLDPE | 20–45 | Grade-dependent |

| HDPE | 25–38 | Higher crystallinity than LDPE |

| PP (homopolymer) | 28–40 | Stiffer; notch-sensitive |

| PP (copolymer) | 25–35 | Better impact; slightly lower strength |

| PVC (rigid) | 40–60 | Plasticized grades: 7–25 |

| PS (general purpose) | 35–60 | Brittle; high clarity |

| HIPS | 20–45 | Impact-modified |

| ABS | 35–55 | Balance of strength/toughness |

| PC | 55–75 | Ductile; high impact |

| PA6 (dry as molded) | 45–85 | Moisture reduces strength, increases ductility |

| PA66 (dry as molded) | 50–90 | Similar moisture sensitivity |

| POM (acetal) | 60–70 | High crystallinity; good creep resistance |

| PMMA (acrylic) | 60–75 | Stiff, relatively brittle |

| PET | 45–70 | Orientation can raise strength |

| PBT | 40–60 | Good dimensional stability |

| PEEK | 90–150 | High-performance semicrystalline |

| PEI | 90–100 | High-Tg amorphous |

| PPS | 55–80 | Chemical/thermal resistant |

| PTFE | 5–15 | Very low strength; excellent chemical resistance |

| UHMWPE | 35–45 | Extremely tough; low modulus |

| LCP (neat) | 150–200 | Highly oriented domains |

| PC + 30% GF | 90–140 | Strong orientation effects |

| PA66 + 30% GF | 100–150 | Values drop with moisture |

| PPS + 40% GF | 120–150 | High stability |

| PEEK + 30% GF | 150–180 | — |

| PEEK + 30% CF | 190–220 | High specific strength |

Why Tensile Strength Matters in Design & Manufacturing

Design decisions and process choices revolve around tensile behavior:

- Safety factors & compliance: Select strength values appropriate to service conditions (temperature, humidity, rate). Avoid using dry‑as‑molded data for moisture‑sensitive polymers in humid service.

- Geometry & features: thin sections, sharp corners, and knit lines are stress risers. Add radii, thicken critical ligaments, and design gates to minimize weld lines in load paths.

- Process–property link: Molding temperature, pack/hold, and cooling rate alter crystallinity and residual stresses; extrusion draw ratios and film blow‑up ratios change orientation and strength.

- Joining: Welded or adhesive joints often govern assembly strength; qualify joints with tensile lap shear and peel testing.

- Anisotropy in AM (3D printing): FFF/FDM parts are weakest Z‑through‑layer; align rasters with principal loads and consider annealing or chemical welding.

Case Snapshots

- Automotive bracket (PA66‑GF30): Gate relocation avoiding the peak tensile path can raise weld‑line strength by >20% in practice.

- Medical clip (POM): Post‑mold anneal increased crystallinity and break strength with minimal cycle time penalty.

- Thin‑wall housing (PC): Adding 0.5 mm to rib base + generous fillets eliminated crack initiation at screw bosses.

How to Improve the Tensile Strength of Polymer Parts

Actionable levers you can apply during development:

- Choose the right grade

- Prefer higher‑Mw or high‑crystallinity grades for strength.

- Use GF/CF reinforcement where stiffness/strength are critical; validate orientation effects.

- Optimize compounding

- Ensure compatibilization in blends (e.g., maleated PP for GF in PP).

- Preserve fiber length (gentle screw profiles, controlled shear).

- Avoid over‑plasticization when strength is paramount.

- Tune processing

- Dry hygroscopic resins (e.g., PA, PET, PC) per supplier spec.

- Adjust melt/mold temps, packing, and cooling to promote desired crystallinity and reduce residual stresses.

- Align flow with principal load directions where possible.

- Design for strength

- Add fillets, avoid sharp notches, and increase load‑bearing cross‑sections.

- Relocate gates to reduce weld lines in tensile regions; use overflow tabs to heal knit lines.

- Postprocessing & validation

- Anneal semi‑crystalline parts when beneficial.

- Use environmental conditioning to match service (humidity/temperature).

- Run DoE to quantify the effect of process windows on tensile outcomes.

Common Pitfalls (and How to Avoid Them)

- Mixing definitions: Reporting UTS as “at break,” or vice‑versa. Always specify what you report and which standard.

- Unit errors: MPa vs. psi typos can be catastrophic; include conversions.

- Ignoring environment: Using dry‑as‑molded PA data for a humid service part—expect a drop in strength.

- Comparing apples to oranges: Different strain rates, specimen types, and orientations make datasets non‑comparable.

- Over‑reliance on datasheets: Supplier data are often from ideal specimens; confirm on production‑representative parts.

- Assuming NDT = strength: NDT finds flaws; it doesn’t replace tensile tests.

FAQs

1) Is tensile strength the same as yield strength?

No. Yield strength marks the onset of permanent deformation. Tensile strength at break refers to the stress at fracture; UTS is the peak stress on the engineering curve—these may differ.

2) Why does strain rate change the strength I measure?

Polymers are viscoelastic. At higher rates, chains have less time to relax, so measured tensile strength typically increases.

3) How does moisture affect polyamides?

Moisture plasticizes PA6/PA66, reducing dry strength but improving ductility. Condition parts to expected service humidity.

4) Can I compare ASTM D638 and ISO 527 numbers?

Only with care. Specimen geometry, gauge length, and speed differ. Always report the method and specimen type used.

5) Why is my GF‑reinforced part weaker than expected?

Likely causes: poor fiber–matrix adhesion, short fiber length due to shear, or unfavorable fiber orientation at the gauge section.

6) Do plasticizers always reduce tensile strength?

Typically yes; they lower Tg and facilitate chain mobility. Use minimally when strength is critical.

7) What’s better to report—engineering or true stress?

Most datasheets use engineering values. For research or large‑strain analysis, report true stress/strain and specify your method.

8) Can NDT replace tensile testing?

No. NDT is excellent for finding flaws but cannot directly quantify tensile strength.

Conclusion

The tensile strength of polymers is not a single immutable number—it is the outcome of molecular architecture, morphology, additives, processing history, environment, and test protocol. By defining terms precisely, adhering to ASTM/ISO methods, and designing with orientation, defects, and service conditions in mind, you can select materials confidently, optimize processing, and avoid brittle surprises in the field.